21 Nov Fashion-Enter Ltd Hosts Free Masterclass on Cost-Effective Sampling and Production

Today, 21st November 2025, more than 22 emerging and start-up brands along with FC Designer Workspace residents joined Fashion-Enter Ltd’s free online masterclass, The Secrets Behind Cost-Effective Sampling and Production for Aspiring Brands and Designers. Led by FEL’s Technical and Production Director Claire Solley, the one-hour Zoom session equipped start-ups with the practical knowledge needed to navigate the complexities of fashion sampling and production without unnecessary cost and waste.

The event focused on helping young labels streamline their processes, avoid common pitfalls, and optimise resources, crucial skills for brands looking to transition from concept to commercial product with confidence and efficiency.

Claire delivered the masterclass through five structured sections designed to demystify the sampling and production workflow for new designers.

1. Introduction to Sampling and Production

The session opened with an overview of why cost-effective sampling is essential for start-up brands. Claire broke down the core stages of the sampling and production process and highlighted common challenges that emerging designers face, from miscommunication with factories to spiralling sampling costs.

2. Planning and Preparation

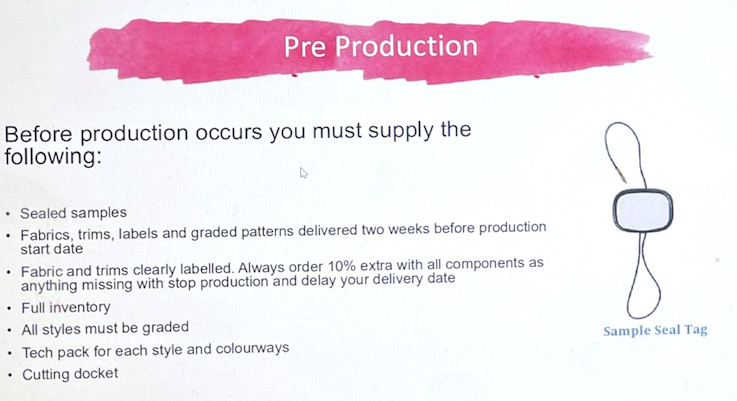

Participants learned how to build a strategic production plan and timeline, source materials efficiently, and manage suppliers. Claire emphasised the importance of accurate tech packs and specifications, explaining how clarity at this stage prevents costly errors later in the process.

3. Streamlining the Sampling Process

Clear communication with sample makers and manufacturers emerged as a key theme. Claire offered real-world tips for reducing costs during sampling, ensuring quality control, and reviewing samples for fit, construction, and materials before moving forward.

4. Efficient Production Techniques

Attendees were introduced to lean manufacturing principles aimed at minimising waste and boosting productivity. Strategies for material utilisation, inventory management, and fostering strong, mutually beneficial relationships with manufacturers were also explored.

5. Quality Assurance and Post-Production

The final section focused on maintaining quality throughout production. Claire explained the importance of thorough inspections, issue-resolution processes, and the logistics considerations required once finished products are ready for shipping and fulfilment.

The masterclass concluded with an interactive Q&A session. One of the most engaging discussions centred on the use of Style3D to significantly reduce or even eliminate the need for physical samples. Participants were keen to understand how virtual sampling can cut costs, speed up development cycles and support more sustainable workflows.

Attendees praised the clarity, depth, and practicality of the session. Many commented on how valuable it was to gain insider knowledge directly from an industry expert. The masterclass succeeded not only in sharing technical insights but also in boosting the confidence of emerging designers as they continue to build their brands.

Sorry, the comment form is closed at this time.